- HOME

- PRODUCTS

-

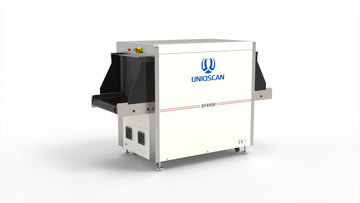

BAGGAE SCANNER

X-Ray Baggage Scanner

-

METAL DETECTOR

Walk Through Metal Detector

-

TURNSTILE

Turnstile Gate

-

UVSS

Under Vehicle Security

- CASE

- NEWS

- FAQ

My Account

We will send you an email to reset your password.

Search our store

Popular Searches:

""